The Bentil Group is equipped with the following facilities:

Advanced Blast Simulator (ABS): Oxyacetylene-Driven.

The advanced blast simulator is used to simulate blast wave exposure, in support of blast-induced traumatic injury research. Click here to learn more about the ABS.

ABS design and fabrication was by Stumptown Research and Development (https://www.stumptownresearch.com/).

Shock Tube: Oxyacetylene-Driven.

The oxyacetylene shock tube is used to simulate blast wave exposure, in support of blast-induced traumatic injury research and dynamic inflation experiments. The inner diameter of the shock tube is 7.62 cm (3-in.) with a 30.48 cm (1-ft) driver and 457.2 cm (15-ft) driven section. Click here to view the video of the oxyacetylene shock tube in action.

Iowa State University’s first oxyacetylene-driven shock tube. Designed by William J. Jackson, for The Bentil Group.

Shock tube fabrication was by Central Iowa Machine Shop (http://centraliowamachine.com/), Iowa State University’s Machine Shop in the Department of Chemistry, and William J. Jackson (Jack).

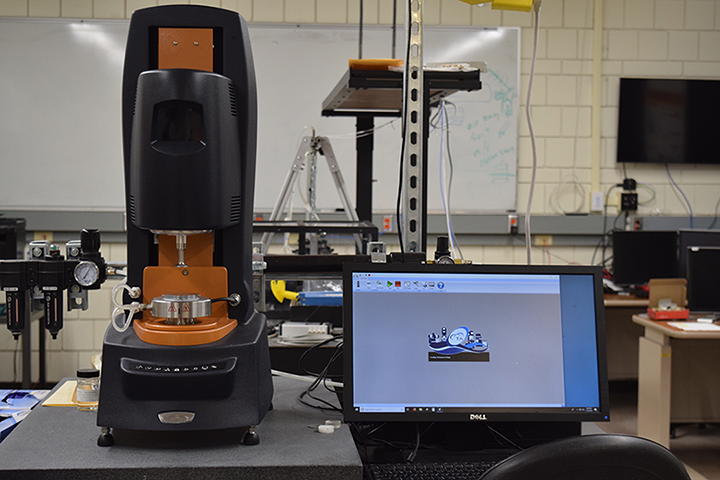

Discovery hybrid rheometer (hr-2).

General purpose rheometer for soft material property characterization. HR-2 is capable of both axial and torsional loading.

TA Instruments.

Other facilities

- Propane-driven shock tube for blast impact research

- Compression-driven shock tubes for blast impact research

- High-speed digital monochrome cameras (Photron FASTCAM SA-Z)

- Optical tables (Newport)

- Digital image correlation software (Correlated Solutions)

- Sterilizer for decontamination and sterilization (Market Forge)

- Biosafety cabinet (Nuaire Class II, Type A2)

- Fume hood (Mott)

The Bentil Group’s facilities are housed in a Biosafety Level 2 (BSL-2) laboratory. A BSL-2 laboratory is suitable for research involving agents that pose moderate hazards to personnel and the environment.