1058 Black Engineering | me_aml@iastate.edu

The Additive Manufacturing Lab is a fee-for-service fabrication space within the Department of Mechanical Engineering that specializes in 3D printing and other advanced fabrication techniques. Our lab is available to support anyone on the ISU campus, including students, faculty, and affiliated clubs or organizations.

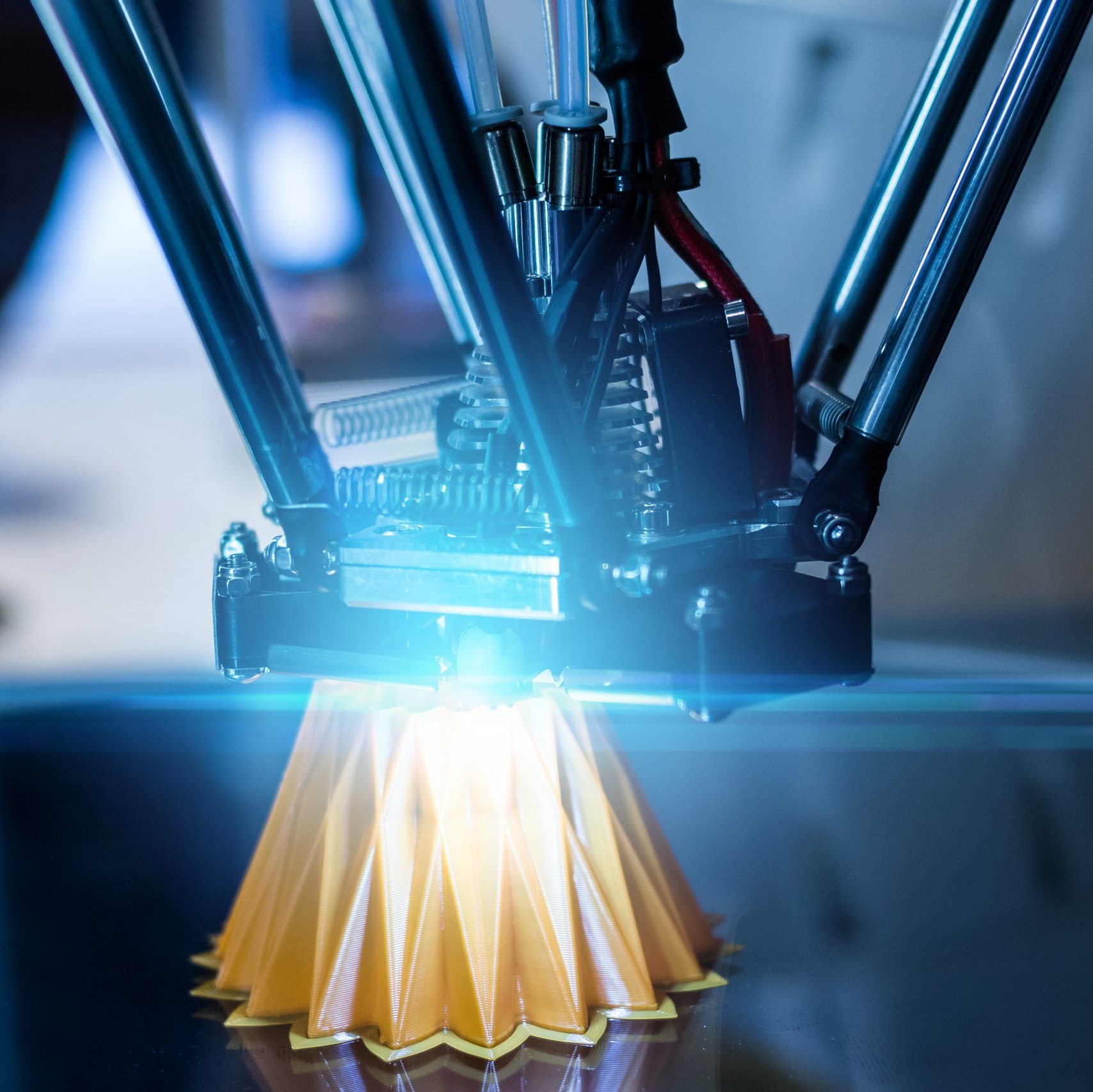

Plastic Printing

Our lab has a variety of plastic printing capabilities that should meet just about anyone’s needs. We have several hobby-grade printers to handle lower-quality parts in limited types of plastic, as well as several industry-grade printers, like the Fortus 250 and 450MC, to produce higher- quality parts in a variety of engineering-grade materials.

Capabilities:

– Plastic parts

– Low to medium-cost prints

– Low to medium-resolution prints (with visible layer lines and artifacts)

– Engineering-grade materials

Learn More

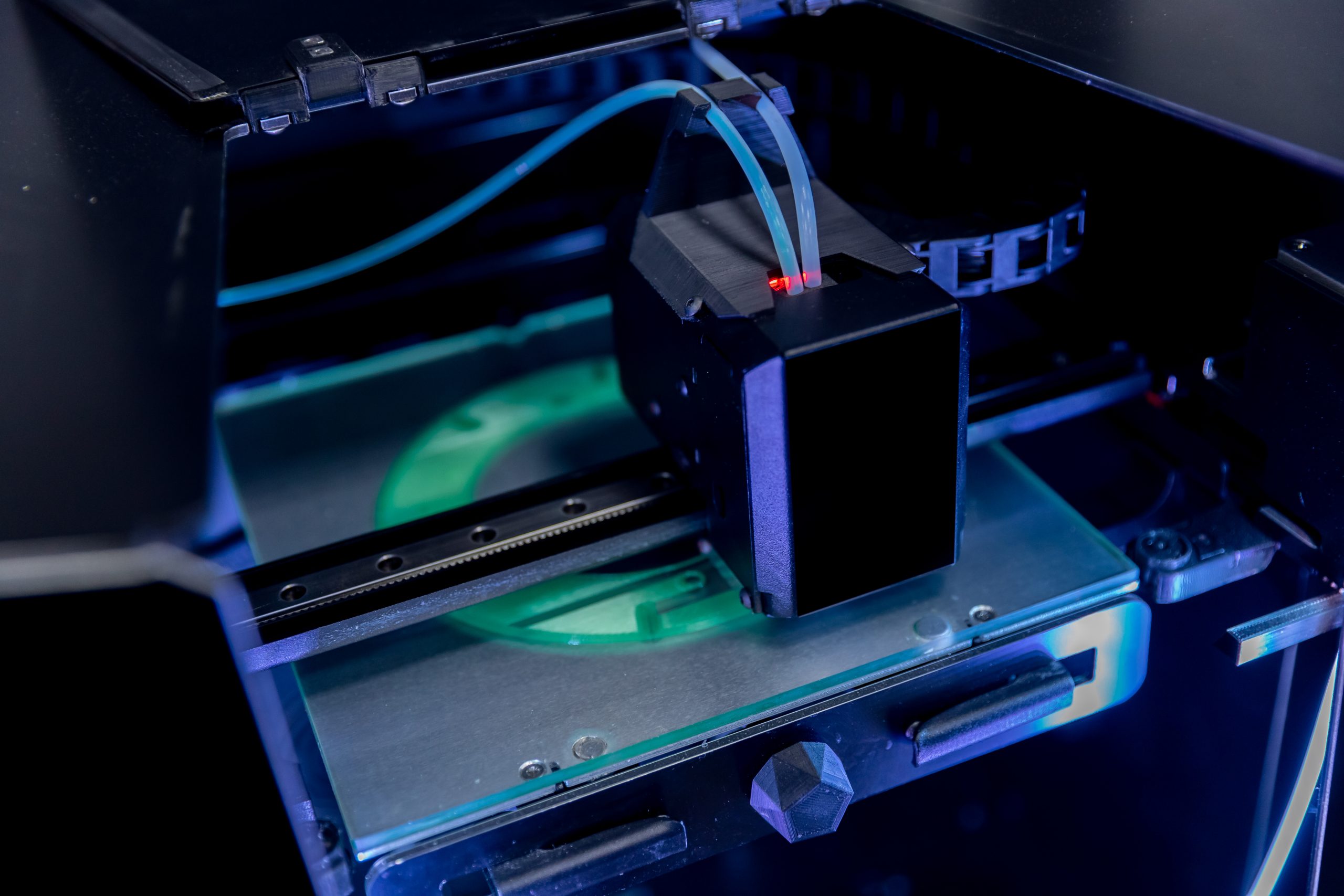

Resin (SLA) Printing

With our Formlabs Form3 SLA resin printer, we can produce high-resolution prints in a variety of materials with different flexibilities and heat capabilities.

Capabilities:

– Plastic parts

– Medium to high-cost prints

– High-resolution prints (minimal layer lines and artifacts)

– A variety of materials

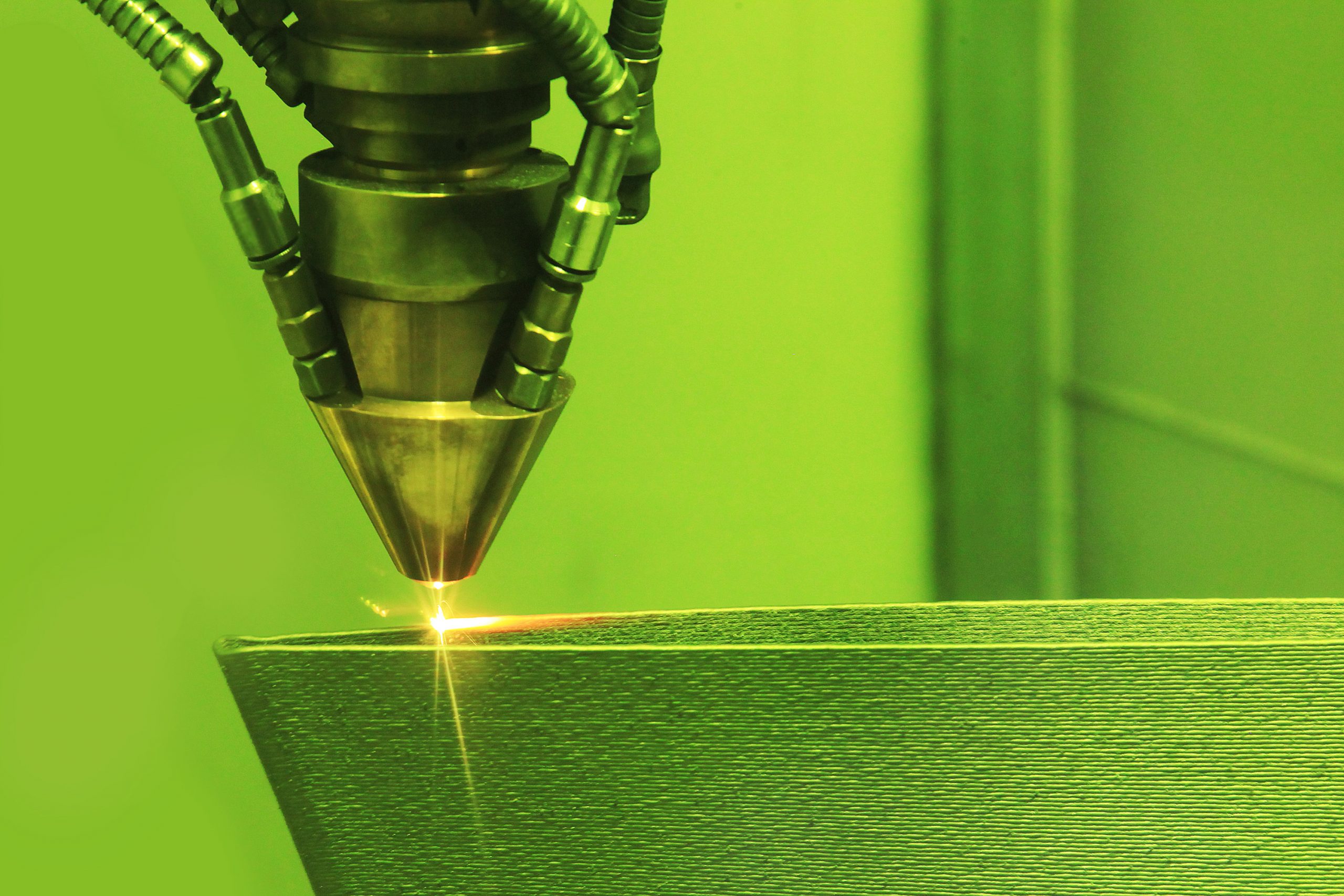

Metal Printing

Using our Desktop Metal Studio 2 system, we can produce metal parts in 17-4 stainless steel. This system uses polymer-bound metal to print parts, which are then sintered in a furnace to bake out the plastics and fuse the metal particles together to make a fully metal part.

Capabilities:

– Metal parts

– Medium-cost prints

– Low to medium-resolution prints (visible layer lines and artifacts)

– Parts with similar quality as a “cast part”

– Parts with material properties equivalent to “as wrought parts”

– Parts have some geometric limitations

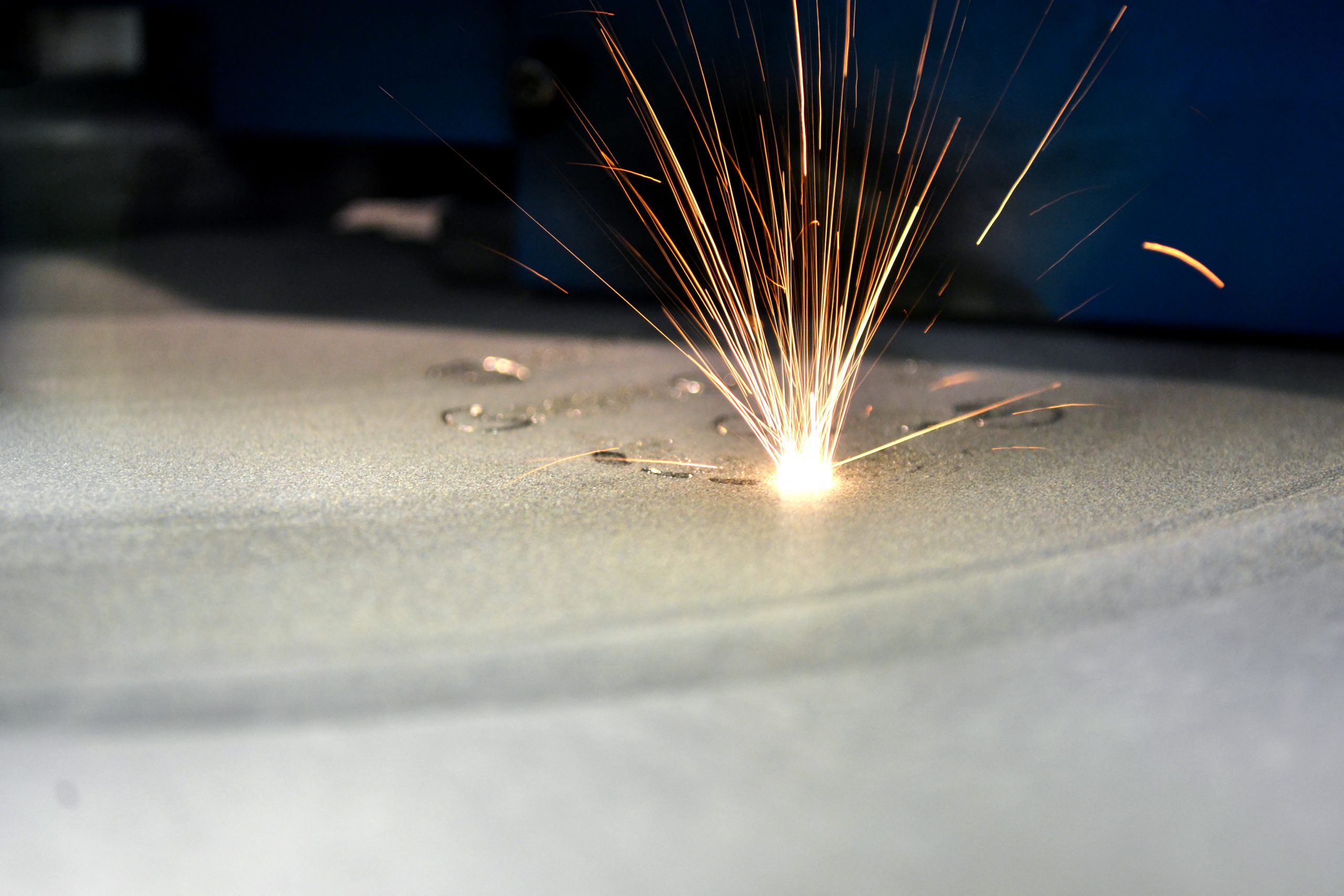

Laser Cutting

In addition to printing things, the AML also has an industry-grade Universal laser cutter capable of cutting and etching a variety of materials in a traditional 2-axis, flat pattern. Additionally, this machine has a rotary axis allowing for cutting and etching round components that fit the material and size limitations of the equipment.

Capabilities:

– Laser cutting in plastics or woods

– 2D etching in plastics, woods, or certain metals

– Rotary cutting or etching in plastics, woods, or certain metals

Micro Milling

Our lab offers unique micro-milling capabilities. This process uses a precise and high spindle speed CNC mill to cut intricate geometry into parts. This process can produce features as small as a few thousandths of an inch. This process is typically used in making components for microfluidic experiments or milling intricate features into circuit boards.

Capabilities:

– Low to medium-cost machining

– High-precision features

– Very small features on the scales of hundredths to thousandths of an inch

– Relatively small parts (4” by 4” max)

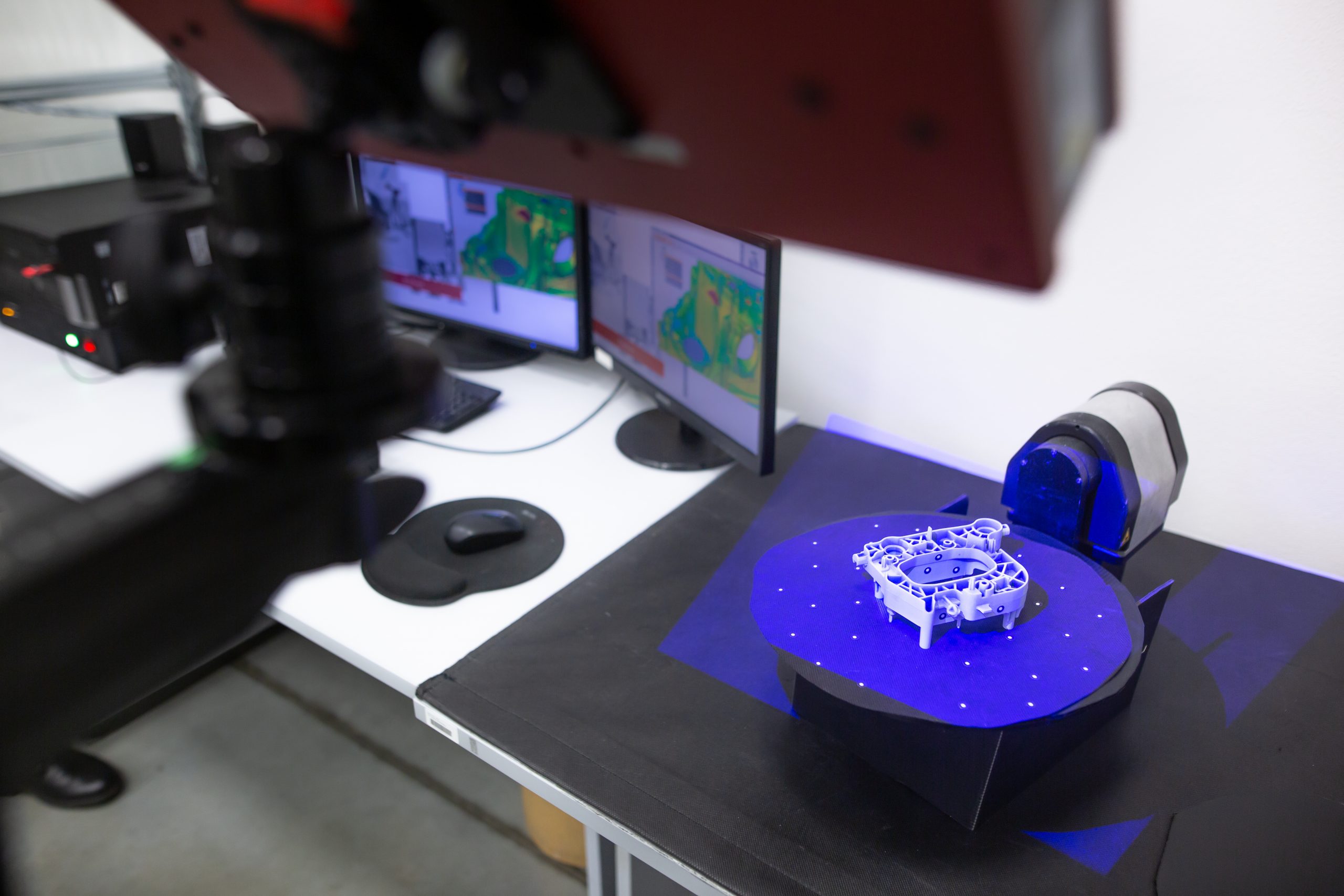

3D Scanning

3D scanning is a very useful technology that can aid in reverse-engineering components, getting mesh data on complicated objects, and even do tolerance studies comparing CAD models to real-world objects. The AML has a handheld, portable Creaform 3D scanner that can scan small to fairly large objects with very high resolution.

Capabilities:

– Low-cost scanning

– Obtain mesh data on objects, reverse-engineer objects, or check tolerances of real objects vs. CAD models

– Scans of parts 1” cubed to 30” cubed in size